F26A0 booster buffer

Category:

Rotary buffer

Hotline:

- Detailed

-

Product Specifications

model torque Torque output direction F26A0-L403

4.0N·m

(40Kgf.cm)

counterclockwise F26A0-L503

5.0N·m

(50Kgf.cm)

counterclockwise F26A0-L603

6.0N·m

(60Kgf.cm)

逆时针方向

F26A0-L703

7.0N·m

(70Kgf.cm)

counterclockwise F26A0-L803

8.0N·m

(80Kgf.cm)

counterclockwise F26A0-L903

9.0N·m

(90Kgf.cm)

counterclockwise Note (1) The F26A0 series is a power-assisted opening type buffer, and the clockwise power assist is more than 30% of the counter-clockwise torque in design;

Note (2) The specification torque is the data when the temperature is 23±2℃;

Note (3) Special torque customization can be provided by changing the viscosity of the shock absorber viscous oil.

use angle 120°

Operating temperature range -5~50℃

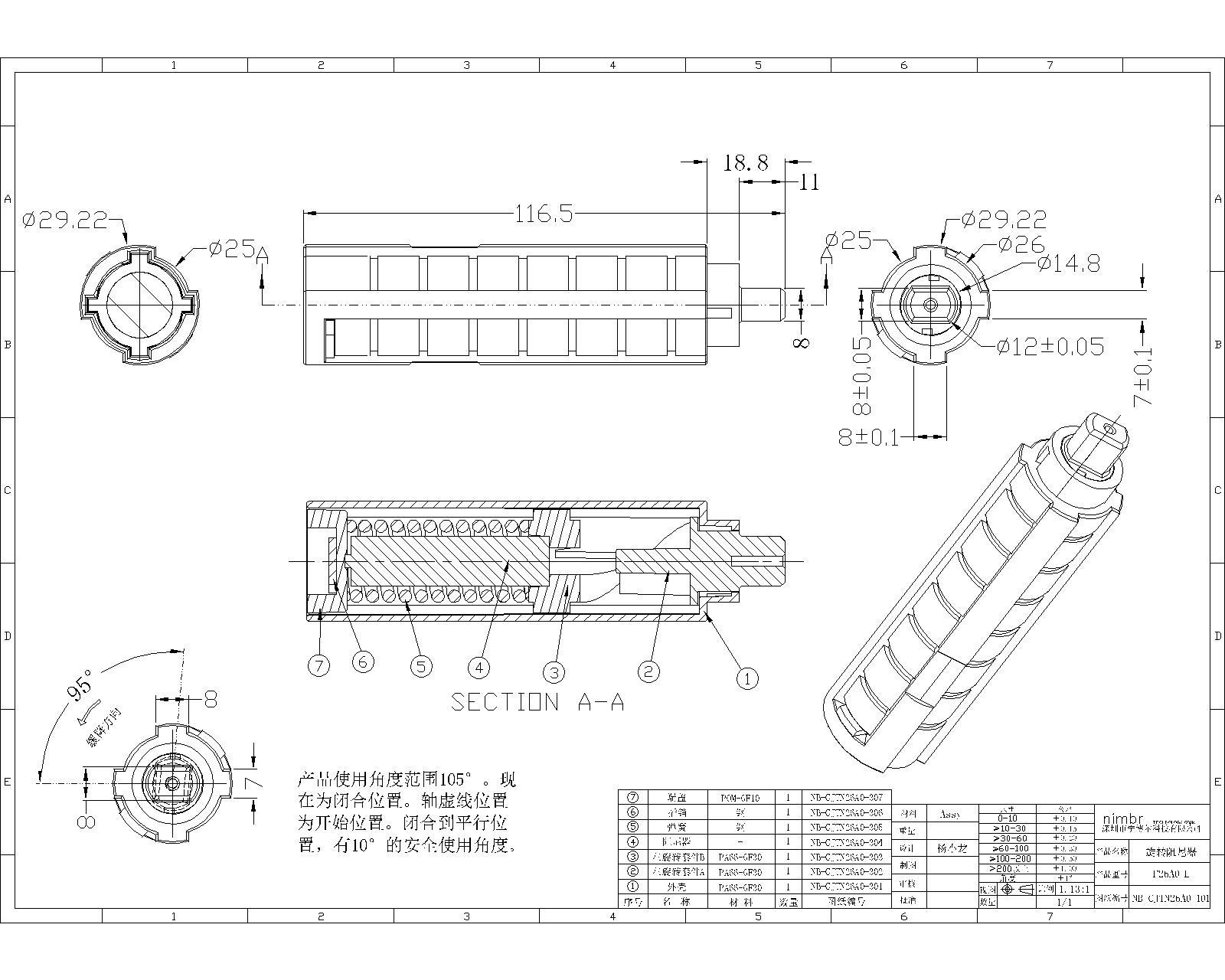

Material of housing and end caps PA plastic Rotary shaft material PA plastic use oil silicone oil Dimensions

Instructions for use

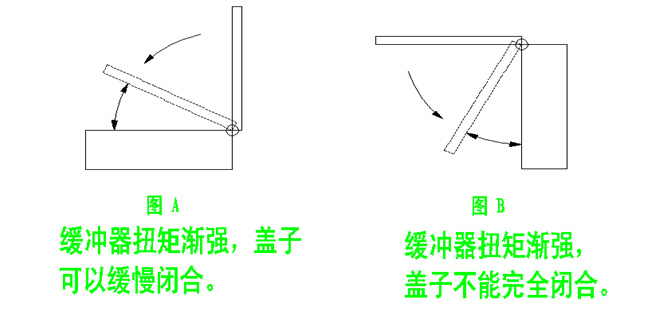

1. When the F26A0 series rotary buffer starts to fall from the vertical position as shown in Figure A to the horizontal position, since the designed torque is weak at the starting position, the torque gradually increases with the rotation of the buffer angle, so the action of the cover can be delayed. Close slowly. As shown in Figure B, when the cover starts to fall from the horizontal position, the torque generated by the gravity of the cover is zero in the vertical direction, and the torque is large at the rear position of the buffer, so the cover cannot be closed.

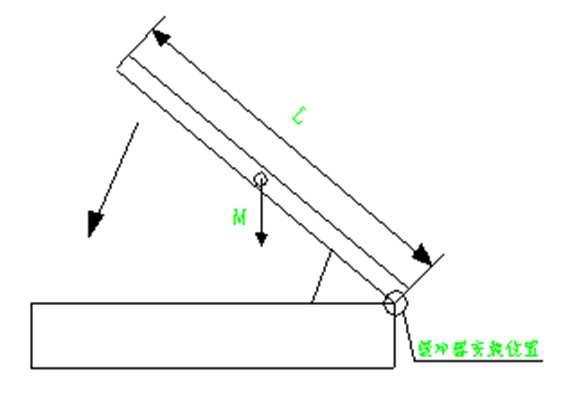

2. When using the rotary buffer in the example shown in the figure, please calculate the required torque according to the following calculation method.

example:

Cover weight M: 3.0kg

The length L of the rotating shaft from the edge of the cover plate: 0.4m

Load torque: T=3.0×9.8×0.4÷2

=5.88N m

From the above calculation we select the buffer as F26A0-L603.

3. Please minimize the gap between the rotary shaft and the joint parts. If there is a gap, the speed of the cover plate will be affected when it is rotated and dropped.

4. The torque of the shock absorber also changes according to the change of the ambient temperature. The change rule is that when the ambient temperature increases, the torque decreases, and the action time is accelerated. When the ambient temperature decreases, the torque increases and the action time slows down. This is because the viscosity of the viscous oil also changes when the ambient temperature changes. But when the ambient temperature returns to normal temperature, the torque will also return to its original value.

5. The rotation angle of the F26A0 series rotary buffer is 120 degrees. If the rotation exceeds 120 degrees, the buffer may be damaged. Please install a stop mechanism externally. The angle of action is based on the closed position.

6. The torque generating direction of the buffer varies according to the structure of the buffer. Please select the appropriate buffer according to different usage methods.

Keywords:- buffer

- the

- of

- torque

- is

- to

- when

- cover

- temperature

Key words:

相关产品

undefined

Messages

Service Line:

A701, Building 1, Hainengda Technology Factory, No. 3 Baolong Fourth Road, Baolong Community, Baolong Street, Longgang District, Shenzhen

0755-89253101